Electromagnetic thermal propulsion and collision effect methods.

1. Thermal electromagnetic propulsion is based on thermal expansion of materials like metals. In the process the electromagnetic energy is changed to work - kinetic energy to propel vehicles with application of untypical guideway the vehicle is moving ahead. This internal energy is coming from the atomic structure of metallic solids medium. After delivering the heat energy to the atoms in solids atoms start to increase external dimensions of its structure. Obtained in that way changes in geometric dimensions are predicted to give away mechanical energy with the application of precisely setting of double surfaces. Thermal energy is directly converted into mechanical energy in this case. The application of wheels is optional and less practical. To proper functioning of the entire system there is a need to apply the axial vibration generators made from hard and heat resistant materials due to the generators may generate a lot of heat because of friction, which heat will be returning to expansion sustaining system at the same generators, what will increase the efficience of entire system. After the system is warmed up with external sources of heat, should be sustaining heat from the friction so the system has automatic delivery of energy after it start to move ahead. The system for now is predicted to work with efficient coolant but this efficiency is depending on geometry of entire movement track, the more inclined track means the more powerful acceleration, but one should remember that this inclination can't be too big, because there is no such a material due to thermal expansion which could be here used. The system will work with not big inclination of the track and with a proper length of the partial tracks of entire track line due to proper cooling of the system and reheating. One should remember that the system is based on changing thermal energy delivering to the axial vibration generators to obtain the changing geometry of the cores ot those generators.

System which is making available two directional movement with respect of heating or cooling, which is a proces depending on which way the vehicle is moving.

Cross section of the train and the track with axial vibration generators.

This system of propulsion is designed for small ground levels differences. The track must be in the range of inclination allowing the vehicle to move on the track which is approximately perpendicular to gravity vector acting as the planetary mass. So, the better result applying this technology is such a designing of the track place which will mean not a lot of displacement in vertical plane.

The system is capable to disturb Earth's gravity field on the deck of the vehicle. The system also should be considered as potentially able to control gravity vector on the deck with great velocity of the vehicle.

The propulsion method can be obtained by using mechanical resonance - once the vertical movement of axial vibration generator stater core is switched on the system should automatically undertake the work and the slightly warming up the system should give the proper speed control of the vehicle. Everything is depending on the technical parameters of the track and the vehicle software.

Second solution is applying similar method but without thermal surplus energy. The problem with friction between axial vibration generators and track surfaces is important. Previously I was thinking that application of hard metals will be enough to solve this problem, but now I am thinking that a layer of hot air should be pumped between those two surfaces and then system would be free from friction because it will move on smooth air cushion. With the weight of the entire train with all passengers and load system with only direct contact of two surfaces would be less plausible and for sure would be getting too hot during the train movement and at least it would be much harder to even move from the spot ahead.

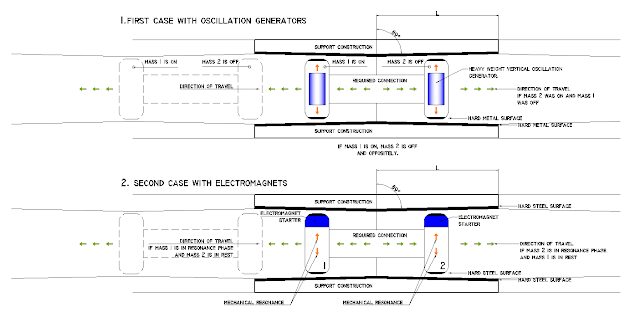

2. The scheme of transport method based on internal collision effects on inclined by one-degree surfaces made from hard, smooth metallic material. The support external construction should be made from stiff reinforced concrete. If movement would be directed to the left, the oscillation of mass one should be turned off once the mass is entering on oppositely inclined surfaces. At the same time, the mass two should be turned on to the oscillation, so the movement would be smooth, and the vehicle could accelerate to the left. Mass is produce thrust only on getting wider in vertical plane surface complying to the direction of travel, and the oppositely connected mass is responsible for oppositely directed movement or for deceleration aims. The oscillation effect should be obtained magnetically or mechanically. The system can consist of many such a mass connected with each other stiffly. There are many ways to avoid increasing friction between masses and the track surfaces. However, if the system would be working fast the real friction would be minimal because the contact with surfaces would be decreased. Masses should be retracted by collision to center position between each of inclined surfaces and each time them do so, they will be moving ahead a little in the demanded direction complying with the gap which will be wider on the other end. The entire difference should be not too big in start position and in end position, because the wider place between the surfaces, the more time the mass will need to overcome the space between them so the velocity will be decreasing fast, especially without an energy addition from the planned source of power.

In the second case there is an opportunity and it is highly recommended to keep both masses in the resonance phase at the same time, so the two-directional movement would be obtained after disturbing a balance between both masses placed on both side of inclinations. If the vibrations coming from the resonance would be greater on one side the balance would be displaced on this side so the train would be moving ahead in complying direction.

What would you people say if I would have found a method to propel trains by use of centrifugal force? I hope that this scheme is readable and clearly describe this method. If you think that this is fake or mistake, tell me in comment where I am wrong in those drawings. This is resonant mass method obtained by two ways. From my early years I am interested of inertial methods of transport also in railway propulsion systems. I have created theoretical base in form of drawings and technical analysis of harnessing Coriolis force for propulsion of ground vehicles like railway vehicles. Inertial energy of Earth is not a fiction and it can propel inertial propelled vehicles. The law of momentum conservation is sustaining that Foucault pendulum will work properly in planetary condition. This is inertial confirmation that inertial propulsion should work if to use proper technology. This technology should rely on intrinsic absorbing of momentum. Today I am working also on the technology based on centrifugal forces which could have an application on railway and this is another kind of inertial based systems not complying with standards and canons of nowadays science and technology. I must admit that this is really weird technology which could be never built but this is technology with no precedens in history of technology created only by me. Conservation of momentum allows to functioning of gyroscope and gyrocompas, and as we can see this property of matter is capable of cancelling gravity forces or absorbing inertia providing geo-inertial systems to life. The shown drawings are demonstrating the method of use high-frequency vibrations to generating low-amplitude oscillations which will be pulling one side of the system with relation to position of inertial chassis inside specific guideways located on upper side and lower side of the train. If the particular chassis is located on left-down and left-up inclined surface the vehicle would be travel to left and if the chassis is located on oppositely inclined surfaces on the other side the train would be travel in opposite side. The gap between resonant mass and surfaces in reality is not so wide as on the drawing which was created for more readiness of the content. Between two resonant masses is connection mage from stiff material, so the centrifugal force will be pulling the rest inactive part of the propulsion system. In order to change direction or deceleration of the train the inactive part will be activated and generate thrust in opposite direction. Of course someone can notice that system will not be able to work because when it will reach end of proper inclined surface there is oppositely inclined surfaces making unable further travel, but there is a solution which is based on clever setting of upper and bottom propulsion guideways. As I have said there are four guideways, rails for entire system just like is shown on the cross section of the tunnel with train. In this solution the guideways are displaced about half a distance to each other in relation to up and down positions, so when the chassis is abandoning one surface on the bottom it is simultaneously entering on another on the top. The cross section is too much simplified, so it can't show the proper working of the system. If the resonant mass would be really heavy the sustaining of the oscillation should be very easy additionally there will be ability of controlling the length of the masses by thermal expansion or by mechanical means. Resonant mass would be connected with entire mass of the vehicle in edge cases the resonant mass should exceed 20-40 percent of the weight of entire train. Thermal expansion would be the way the train will be accelerate and it will be providing controlling of speed on the entire length of the guideway. If the system would to be workable it must be performed with application of steel and hard concrete for the guideways construction. This propulsion system would be working the best underneath the surface of earth in underground tunnels due to need of building approximated to the horizontal plane guideways. This is serious disadvantage but considering this free-energy system of propulsion and such a technical solution the money invested in this method would be quickly returning back to the wallets of the investors for sure.

Simpler version and better.

Komentarze

Prześlij komentarz